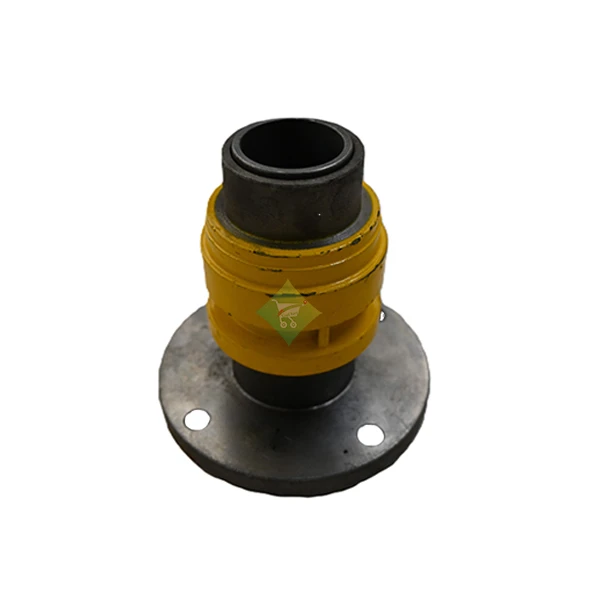

Product Name: Clutch Finger GB-50 CA

Category: Agricultural Machinery Parts / Clutch Components

Description:

The Clutch Finger GB-50 CA is a critical part of the clutch mechanism in agricultural and industrial machinery, specifically designed for use in clutch assemblies where high performance is essential. It is primarily used in equipment such as combine harvesters, tractors, and other heavy-duty machines that require robust and reliable clutch systems. The Clutch Finger GB-50 CA helps facilitate the engagement and disengagement of the clutch plates by applying the appropriate force when the clutch pedal is pressed. Its design ensures a smooth and reliable connection, preventing slipping and maintaining effective power transmission between the engine and the machinery.

Key Features:

Durable Material: Manufactured from high-strength steel or alloy steel, the Clutch Finger GB-50 CA is built to endure the high stress and mechanical pressure typically encountered in clutch systems.

Precision Engineering: Designed with precision to fit perfectly within the clutch assembly, ensuring efficient power transmission and smooth engagement/disengagement of the clutch plates.

Corrosion-Resistant: Often treated with corrosion-resistant coatings, making it suitable for use in outdoor and harsh environments where moisture and dirt exposure is common.

High Performance: Provides consistent pressure for clutch engagement, ensuring that the system functions smoothly without slipping or wear.

Vibration Resistance: Built to withstand the vibrations common in agricultural and construction machinery, ensuring long-lasting performance under demanding conditions.

Applications:

Agricultural Machinery: Used in combine harvesters, tractors, and other agricultural equipment where the clutch system is essential for controlling power transmission between the engine and working parts.

Construction Equipment: Ideal for use in construction machinery such as bulldozers, excavators, and loaders that rely on clutch mechanisms to engage and disengage power transmission efficiently.

Industrial Machinery: Also used in industrial machines like compressors, generators, and conveyors where clutch systems are necessary to control power transfer between components.

Automotive Systems: Can be used in heavy-duty trucks and other vehicles with large clutch systems that require a robust mechanism for efficient power transmission.

Usage Tips:

Proper Installation: Ensure the Clutch Finger GB-50 CA is installed properly within the clutch assembly. Improper installation can lead to inefficient clutch operation and damage to surrounding components.

Regular Maintenance: Periodically inspect the Clutch Finger GB-50 CA for signs of wear, corrosion, or deformation. Replace it if necessary to ensure the clutch system continues to perform efficiently.

Lubrication: Apply appropriate lubrication to clutch components during installation to reduce friction and ensure smooth operation.

Avoid Over-Stressing: Avoid overloading the clutch system, as excessive force can lead to premature wear on the Clutch Finger GB-50 CA and other clutch components.

Monitor Clutch Operation: Keep an eye on the clutch system’s performance. If you notice slipping or difficulty engaging/disengaging the clutch, it may indicate a problem with the Clutch Finger GB-50 CA or other clutch components.

Available Sizes:

Dimensions: The Clutch Finger GB-50 CA is available in various sizes to match specific machinery models. Each size is designed to meet the required pressure specifications of the clutch assembly.

Material Options: Typically made from high-strength steel, alloy steel, or other durable materials to ensure longevity and high performance under heavy mechanical stress.

Design Variations: Available in different designs based on the clutch system's requirements, such as the number of fingers and their specific placement in the clutch assembly.

Why Choose Our Clutch Finger GB-50 CA:

High Durability: Crafted from durable materials, the Clutch Finger GB-50 CA ensures long-lasting performance even under high pressure and mechanical stress.

Consistent Performance: Designed to provide precise force for clutch engagement, it ensures smooth operation of the clutch system and reduces the likelihood of clutch slippage.

Corrosion-Resistant: The spring is often treated with corrosion-resistant coatings, ensuring optimal performance in outdoor and exposed environments.

Vibration-Resistant: Built to handle the mechanical vibrations typically encountered in agricultural and industrial machinery, ensuring reliable function over extended periods.

Cost-Effective: A cost-effective solution for keeping your clutch system in optimal condition, reducing downtime and maintenance costs