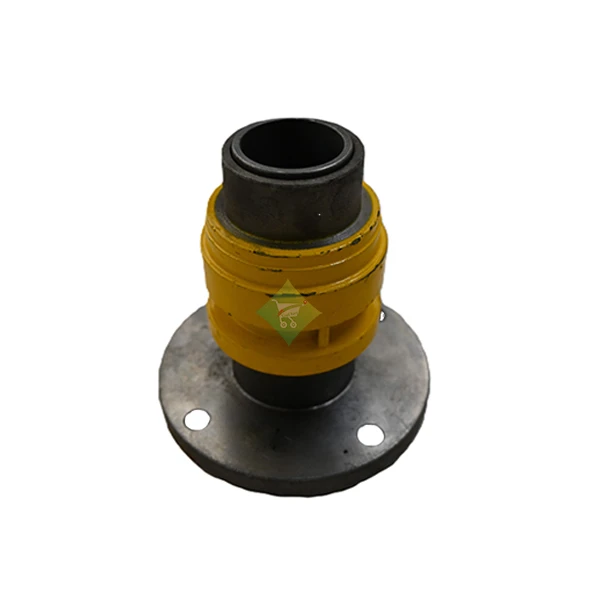

Product Name: Clutch Finger GB-40 CA

Category: Agricultural Machinery Parts / Clutch Components

Description:

The Clutch Finger GB-40 CA is a critical part of the clutch mechanism in agricultural and industrial machinery. It plays a vital role in transferring the pressure required for the engagement and disengagement of the clutch plates. The Clutch Finger GB-40 CA is commonly used in equipment such as combine harvesters, tractors, and other heavy-duty machinery where reliable clutch performance is necessary. By providing the right amount of pressure to the clutch plates, it ensures smooth transmission of power between the engine and the machine’s working parts, enabling effective operation.

Key Features:

Durable Construction: Made from high-tensile steel or alloy materials, the Clutch Finger GB-40 CA is designed to withstand mechanical stress, making it durable under high pressure and frequent use.

Precision Engineering: The finger is manufactured with precise dimensions to ensure it fits perfectly in the clutch assembly, delivering efficient performance and smooth clutch engagement.

Corrosion-Resistant: Coated with anti-corrosion materials, the Clutch Finger GB-40 CA is resistant to rust and damage, ensuring its longevity even when exposed to harsh outdoor conditions.

Reliable Performance: Provides the necessary force to the clutch plates, ensuring smooth operation of the clutch system and preventing issues like slippage or failure.

Vibration Resistance: Engineered to handle mechanical vibrations, ensuring continued reliability and functionality even in high-vibration environments like agricultural and construction machinery.

Applications:

Agricultural Machinery: Used in combine harvesters, tractors, and other farming machinery where the clutch system plays a key role in controlling power transmission between the engine and the machinery.

Construction Equipment: Suitable for use in construction machinery like bulldozers, excavators, and loaders that rely on a robust clutch system to engage and disengage power.

Industrial Equipment: Used in industrial machines, such as generators, compressors, and conveyors, where efficient clutch engagement is necessary for power transfer.

Automotive Systems: Can be applied to heavy-duty vehicles like trucks and buses that rely on large, high-performance clutch systems.

Usage Tips:

Proper Installation: Ensure the Clutch Finger GB-40 CA is installed according to the manufacturer’s instructions to avoid misalignment or improper function of the clutch system.

Regular Inspections: Regularly inspect the Clutch Finger GB-40 CA for any signs of wear, rust, or deformation. A damaged clutch finger should be replaced promptly to maintain the performance of the clutch.

Lubrication: Apply appropriate lubrication during installation to reduce friction and enhance the life of the clutch system.

Avoid Overload: Prevent overloading the clutch system as it can cause excessive wear on the Clutch Finger GB-40 CA and other clutch components.

Monitor Clutch Performance: Keep an eye on the clutch's performance. If you notice slipping, difficulty in engaging, or disengaging the clutch, the Clutch Finger GB-40 CA may require adjustment or replacement.

Available Sizes:

Dimensions: The Clutch Finger GB-40 CA is available in different sizes to match the specifications of various machinery models. Each size is designed to meet the pressure and force requirements of the clutch system.

Material Options: Commonly made from high-tensile steel or alloy steel, ensuring durability and resistance to wear and tear.

Design Variations: Available in different designs and configurations based on the clutch assembly specifications of specific machines.

Why Choose Our Clutch Finger GB-40 CA:

High Durability: Manufactured from strong materials, the Clutch Finger GB-40 CA offers long-lasting reliability and resists wear, making it ideal for high-stress applications.

Smooth Operation: Helps ensure the clutch system engages and disengages smoothly, improving the overall performance of the machine.

Corrosion-Resistant: Protected with anti-corrosion treatments, the Clutch Finger GB-40 CA can withstand exposure to moisture, dirt, and other environmental factors.

Vibration Resistance: Designed to resist mechanical vibrations, ensuring reliable performance even under continuous operation in heavy machinery.

Cost-Effective: A high-performance yet affordable solution that helps maintain clutch system efficiency, reducing downtime and maintenance costs.